In today's dynamic global marketplace, efficiently managing freight forwarding operations is paramount to success. Businesses constantly seek ways to enhance the transportation process, ensuring timely and cost-effective delivery click here of goods across borders. By implementing cutting-edge technologies and embracing best practices, freight forwarders can refine their operations to achieve unprecedented levels of global efficiency.

- Essential to this optimization is the utilization of real-time tracking systems, which provide businesses with a comprehensive insight into the movement of their shipments at every stage.

- Additionally, automation technologies, such as electronic data interchange (EDI), can significantly reduce manual processes, minimizing errors and accelerating lead times.

As a result, optimizing freight forwarding for global efficiency translates to reduced costs, optimized customer satisfaction, and boosted competitiveness in the global marketplace.

Streamlining Warehouse Operations: Maximizing Space and Productivity

In today's dynamic market, warehouse operations necessitate a high level of optimization. Warehouses are the backbone of any supply chain, responsible for receiving goods and processing orders promptly. To thrive in this demanding landscape, businesses must continuously strive strategies to optimize space utilization and improve productivity.

One key factor is implementing a well-designed configuration. This involves intelligently allocating space for different functions, such as receiving, storage, packing, and shipping. Utilizing high- racking systems can dramatically increase storage capacity while minimizing floor space.

Another crucial element is the implementation of technology to automate warehouse processes. Warehouse Management Systems (WMS) can seamlessly track inventory, plan orders, and optimize overall operational flow.

Furthermore, investing in comfortable equipment and training can substantially reduce the risk of workplace injuries while improving employee output.

Regular care of warehouse machinery is also essential to prevent downtime and maintain smooth operations. By routinely addressing any problems, businesses can enhance the lifespan of their assets and minimize costly repairs.

By implementing these solutions, warehouses can optimize their operations, utilize space efficiently, and boost productivity, ultimately contributing to improved customer satisfaction.

Inventory Management Techniques for Improved Supply Chain Transparency

Effective inventory control is paramount to achieving enhanced supply chain visibility. By implementing robust strategies, businesses can track inventory levels in real-time, forecast demand fluctuations, and enhance the flow of goods throughout the supply chain.

Utilizing technologies such as barcode scanning, RFID tagging, and warehouse management systems (WMS) enables businesses to gain a comprehensive view of their inventory position. Furthermore, these technologies facilitate accurate demand forecasting, allowing companies to alter production schedules and procurement plans accordingly.

- Implementing just-in-time (JIT) inventory systems can minimize stock levels while ensuring timely delivery of materials.

- Regularly conducting cycle counts helps identify discrepancies in inventory records and prevent stockouts or overstocking.

- Utilizing vendor-managed inventory (VMI) programs allows suppliers to control inventory levels at the customer's location, minimizing lead times and improving overall efficiency.

Building a Resilient Supply Chain: Overcoming Challenges and Guaranteeing Punctual Arrivals

In today's dynamic global economy, businesses face a myriad of obstacles that can disrupt their supply chains. Unforeseen events, such as natural disasters, political unrest, and epidemics, can create significant hindrances in the movement of goods and services. To reduce these risks and ensure efficient operations, organizations must prioritize supply chain resilience.

A resilient supply chain is one that can tolerate disruptions and rapidly recover from them. This requires a strategic approach that includes diversifying supplier networks, adopting advanced technology, and building strong relationships with key stakeholders.

Moreover, a robust supply chain strategy should prioritize visibility throughout the entire process. By having real-time insights into inventory levels, production schedules, and transportation routes, businesses can recognize potential challenges early on and take preventive actions to avoid delays and disruptions.

By investing in supply chain resilience, organizations can not only confirm on-time delivery but also improve their overall business performance.

Leveraging Technology for Intelligent Inventory Management

In today's fast-paced business environment, effective inventory management is vital for success. Companies of all dimensions are increasingly adopting advanced technologies to optimize their inventory processes and achieve greater efficiency. From cloud-based tracking systems to analytical forecasting tools, technology is transforming the way businesses manage their inventory.

- By leveraging these advanced technologies, companies can achieve a range of benefits, such as:

- Reduced inventory costs

- Enhanced order fulfillment rates

- Increased customer satisfaction

- Real-time visibility into inventory levels

Ultimately, intelligent inventory management powered by technology empowers organizations to operate more productively. It allows them to forecast demand, streamline stock levels, and minimize waste, leading to a viable competitive advantage.

Building a Resilient and Flexible Supply Chain Network

In today's dynamic global marketplace, organizations are increasingly demanding supply chain networks that can effectively adapt to changing market conditions. Building a sustainable and agile supply chain network requires a holistic approach that encompasses various aspects, including {technologyimplementation, cooperation with suppliers and customers, and a strong commitment to sustainability.

- Leveraging advanced technologies such as blockchain and artificial intelligence can optimize supply chain visibility and traceability.

- Fostering collaborative relationships with suppliers and customers can mitigate risks and enhance overall performance.

- Integrating sustainable practices throughout the supply chain can reduce environmental impact and enhance brand reputation.

Jake Lloyd Then & Now!

Jake Lloyd Then & Now! Alicia Silverstone Then & Now!

Alicia Silverstone Then & Now! Marla Sokoloff Then & Now!

Marla Sokoloff Then & Now! Kane Then & Now!

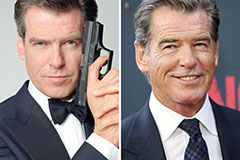

Kane Then & Now! Pierce Brosnan Then & Now!

Pierce Brosnan Then & Now!